Introduction

Borosilicate glass 3.3 pipeline components are widely used in chemical, pharmaceutical and allied industries together with other applications such as food and drugs, dye production and electroplating industries. This is because of the special properties of borosilicate glass 3.3.

- Smooth Surfaces allow easy cleaning and sterilization and prevent the build–up of solids on the inner walls.

- With almost universal resistance to corrosion, a long service life is guaranteed and maintenance is kept to a minimum.

- Their transparency permits visual monitoring of the process at all times.

- Being inert, the risk of contamination is negligible.

Pipeline Components

| L | CAT. REF.DN 15 | CAT. REF.DN 25 | CAT. REF.DN 40 | CAT. REF.DN 50 |

|---|---|---|---|---|

| 75 | HPS07/75 | - | - | - |

| 100 | HPS07/100 | HPS1/100 | HPSI.5/100 | HPS2/100 |

| 150 | HPS07/150 | HPSI /150 | HPS1.5/150 | HPS2/150 |

| 200 | HPS07/200 | HPS1/200 | HPS1.5/200 | HPS2/200 |

| 250 | HPS07/250 | HPS1/250 | HPS1.5/250 | HPS2/250 |

| 300 | HPS07/300 | HPS1 /300 | HPS1.5/300 | HPS2/300 |

| 400 | HPS07/400 | HPS1/400 | HPS1.5/400 | HPS2/400 |

| 500 | HPS07/500 | HPS1/500 | HPS1.5/500 | HPS2/500 |

| 600 | HP507/600 | HPS1 /600 | HPS1.5/600 | HPS2/600 |

| 750 | HP507/750 | HPS1/750 | HPS15/750 | HPS2/750 |

| 900 | HP507/900 | HPS1/900 | HPS1.5/900 | HPS2/900 |

| 1000 | HPS07/1000 | HPS1/1000 | HPS1.5/1000 | HPS2/1000 |

| L | CAT. REF.DN 80 | CAT. REF.DN 100 | CAT. REF.DN 15 |

|---|---|---|---|

| 100 | HPS3/100 | HPS4/100 | HPS6/100 |

| 150 | HPS3/150 | HPS4/150 | HPS6/150 |

| 200 | HPS3/200 | HPS4/200 | HPS6/200 |

| 250 | HPS3/250 | HPS4/250 | HPS6/250 |

| 300 | HPS3/300 | HPS4/300 | HPS6/300 |

| 400 | HPS3/400 | HPS4/400 | HPS6/400 |

| 500 | HPS3/500 | HPS4/500 | HPS6/500 |

| 600 | HPS3/600 | HPS4/600 | HPS6/600 |

| 750 | HPS3/750 | HPS4/750 | HPS6/750 |

| 900 | HPS3/900 | HPS4/900 | HPS6/900 |

| 1000 | HPS3/1000 | HPS4/1000 | HPS6/1000 |

| L | CAT. REF.DN 225 | CAT. REF.DN 300 |

|---|---|---|

| 300 | HPS9/300 | HPS12/300 |

| 400 | HPS9/400 | HPS12/400 |

| 500 | HPS9/500 | HPS12/500 |

| 600 | HPS9/600 | HPS12/600 |

| 750 | HPS9/750 | HPS12/750 |

| 900 | HPS9/900 | HPS12/900 |

| 1000 | HPS9/1000 | HPS12/1000 |

| 1200 | HPS9/1200 | HPS12/1200 |

| 1500 | HPS9/1500 | HPS12/1500 |

| L | CAT. REF.DN 400 | CAT. REF.DN 450 | CAT. REF.DN 600 |

|---|---|---|---|

| 300 | HPS16/300 | HPS18/300 | HPS24/300 |

| 500 | HPS16/500 | HPS18/500 | HPS24/500 |

| 750 | HPS16/750 | HPS18/750 | HPS24/750 |

| 1000 | HPS16/1000 | HPS18/1000 | HPS24/1000 |

| 1500 | HPS16/1500 | HPS18/1500 | HPS24/1500 |

Spacer is used to make small increments in length and is fitted between standard pipe line components . When incorporating the spacer, longer coupling bolts are required with additional gasket.Spacer are also available in PTFE

| DN | L | TYPE | CAT. REF |

|---|---|---|---|

| 15 | 5 | A | HSS07/5 |

| 15 | A | HSS07/15 | |

| 20 | A | HSS07/20 | |

| 25 | B | HSS07/25 | |

| 50 | B | HSS07/50 | |

| 25 | 5 | A | HSS1/5 |

| 15 | A | HSS1/15 | |

| 20 | A | HSS1/20 | |

| 25 | B | HSS1/25 | |

| 50 | B | HSS1/50 | |

| 40 | 5 | A | HSS1.5/5 |

| 15 | A | HSS1.5/15 | |

| 20 | A | HSS1.5/20 | |

| 25 | B | HSS1.5/25 | |

| 50 | B | HSS1.5/50 | |

| 75 | B | HSS1.5/75 | |

| 50 | 5 | A | HSS2/5 |

| 15 | A | HSS2/15 | |

| 20 | A | HSS2/20 | |

| 25 | B | HSS2/25 | |

| 50 | B | HSS2/50 | |

| 75 | B | HSS2/75 | |

| 80 | 5 | A | HSS3/5 |

| 15 | A | HSS3/15 | |

| 20 | A | HSS3/20 | |

| 25 | B | HSS3/25 | |

| 50 | B | HSS3/50 | |

| 75 | B | HSS3/75 | |

| 100 | B | HSS3/100 |

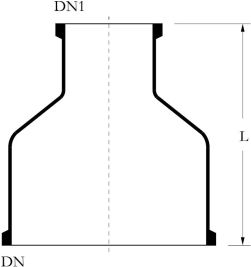

| DN | DN1 | L | CAT. REF. |

|---|---|---|---|

| 25 | 15 | 75 | HPR1/07 |

| 40 | 15 | 100 | HPR1.5/07 |

| 40 | 25 | 100 | HPR1.5/1 |

| 50 | 15 | 100 | HPR2/07 |

| 50 | 25 | 100 | HPR2/1 |

| 50 | 40 | 100 | HPR2/1.5 |

| 80 | 15 | 100 | HPR3/07 |

| 80 | 25 | 125 | HPR3/1 |

| 80 | 40 | 125 | HPR3/1.5 |

| 80 | 50 | 125 | HPR3/2 |

| 100 | 15 | 125 | HPR4/07 |

| 100 | 25 | 150 | HPR4/1 |

| 100 | 40 | 150 | HPR4/1.5 |

| 100 | 50 | 150 | HPR4/2 |

| 100 | 80 | 150 | HPR4/3 |

| 150 | 25 | 200 | HPR6/1 |

| 150 | 40 | 200 | HPR6/1.5 |

| 150 | 50 | 200 | HPR6/2 |

| 150 | 80 | 200 | HPR6/3 |

| 150 | 100 | 200 | HAPR6/4 |

| 225 | 25 | 250 | HPR9/1 |

| 225 | 40 | 250 | HPR9/1.5 |

| 225 | 50 | 250 | HPR9/2 |

| 225 | 80 | 250 | HPR9/3 |

| 225 | 100 | 250 | HAPR9/4 |

| 225 | 150 | 250 | HAPR9/6 |

| 300 | 25 | 300 | HPR12/1 |

| 300 | 40 | 300 | HPR12/1.5 |

| 300 | 50 | 300 | HPR12/2 |

| 300 | 80 | 300 | HPR12/3 |

| 300 | 100 | 300 | HPR12/4 |

| 300 | 150 | 300 | HPR12/6 |

| 300 | 225 | 300 | HPR12/9 |

| 400 | 25 | 350 | HPR16/1 |

| 400 | 40 | 350 | HPR16/1.5 |

| 400 | 50 | 350 | HPR16/2 |

| 400 | 80 | 350 | HPR16/3 |

| 400 | 100 | 350 | HPR16/4 |

| 400 | 150 | 350 | HPR16/6 |

| 400 | 225 | 350 | HPR16/9 |

| 400 | 300 | 350 | HPR16/12 |

| 450 | 25 | 350 | HPR18/1 |

| 450 | 40 | 350 | HPR18/1.5 |

| 450 | 50 | 375 | HPR18/2 |

| 450 | 80 | 375 | HPR18/3 |

| 450 | 100 | 375 | HPR18/4 |

| 450 | 150 | 375 | HPR18/6 |

| 450 | 225 | 375 | HPR18/9 |

| 450 | 300 | 375 | HPR18/12 |

| 600 | 100 | 400 | HPR24/4 |

| 600 | 150 | 400 | HPR24/6 |

| 600 | 225 | 425 | HPR24/9 |

| 600 | 300 | 425 | HPR24/12 |

| 600 | 450 | 475 | HPR24/18 |

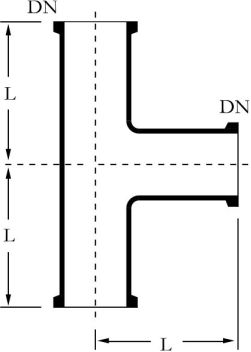

| DN | L | CAT. REF |

|---|---|---|

| 15 | 50 | HPT07 |

| 25 | 100 | HPT1 |

| 40 | 150 | HPT1.5 |

| 50 | 150 | HPT2 |

| 80 | 200 | HPT3 |

| 100 | 250 | HPT4 |

| 150 | 250 | HPT6 |

| 225 | 375 | HPT9 |

| 300 | 450 | HPT12 |

| DN | DN1 | L | L1 | CAT. REF. |

|---|---|---|---|---|

| 25 | 15 | 150 | 75 | HPTU1/07 |

| 40 | 15 | 200 | 75 | HPTU1.5/07 |

| 40 | 25 | 200 | 75 | HPTU1.5/1 |

| 50 | 15 | 200 | 80 | HPTU2/07 |

| 50 | 25 | 200 | 80 | HPTU2/1 |

| 50 | 40 | 200 | 100 | HPTU2/1.5 |

| 80 | 15 | 250 | 100 | HPTU3/07 |

| 80 | 25 | 250 | 100 | HPTU3/1 |

| 80 | 40 | 250 | 100 | HPTU3/1.5 |

| 80 | 50 | 250 | 115 | HPTU3/2 |

| 100 | 15 | 250 | 100 | HPTU4/07 |

| 100 | 25 | 250 | 110 | HPTU4/1 |

| 100 | 40 | 250 | 125 | HPTU4/1.5 |

| 100 | 80 | 300 | 150 | HPTU4/3 |

| 150 | 25 | 250 | 150 | HPTU6/1 |

| 150 | 40 | 250 | 150 | HPTU6/1.5 |

| 150 | 50 | 250 | 150 | HPTU6/2 |

| 150 | 80 | 300 | 200 | HPTU6/3 |

| 150 | 100 | 300 | 200 | HPTU6/4 |

| 225 | 25 | 300 | 185 | HPTU9/1 |

| 225 | 40 | 300 | 185 | HPTU9/1.5 |

| 225 | 50 | 300 | 185 | HPTU9/2 |

| 225 | 80 | 300 | 210 | HPTU9/3 |

| 225 | 100 | 450 | 250 | HPTU9/4 |

| 225 | 150 | 450 | 275 | HPTU9/6 |

| 300 | 25 | 400 | 230 | HPTU12/1 |

| 300 | 40 | 400 | 230 | HPTU12/1.5 |

| 300 | 50 | 400 | 230 | HPTU12/2 |

| 300 | 80 | 400 | 275 | HPTU12/3 |

| 300 | 100 | 400 | 275 | HPTU12/4 |

| 300 | 150 | 450 | 300 | HPTU12/6 |

| 300 | 225 | 600 | 300 | HPTU12/9 |

| 400 | 40 | 400 | 275 | HPTU16/1.5 |

| 400 | 50 | 400 | 275 | HPTU16/2 |

| 400 | 80 | 400 | 300 | HPTU16/3 |

| 400 | 100 | 400 | 300 | HPTU16/4 |

| 400 | 150 | 500 | 350 | HPTU16/6 |

| 400 | 225 | 800 | 450 | HPTU16/9 |

| 400 | 300 | 800 | 450 | HPTU16/12 |

| 450 | 40 | 400 | 300 | HPTU18/1.5 |

| 450 | 50 | 400 | 300 | HPTU18/2 |

| 450 | 80 | 400 | 320 | HPTU18/3 |

| 450 | 100 | 400 | 320 | HPTU18/4 |

| 450 | 150 | 600 | 380 | HPTU18/6 |

| 450 | 225 | 800 | 400 | HPTU18/9 |

| 450 | 300 | 800 | 400 | HPTU18/12 |

| 600 | 100 | 600 | 450 | HPTU24/4 |

| 600 | 150 | 600 | 450 | HPTU24/6 |

| 600 | 225 | 800 | 525 | HPTU24/9 |

| 600 | 300 | 800 | 525 | HPTU24/12 |

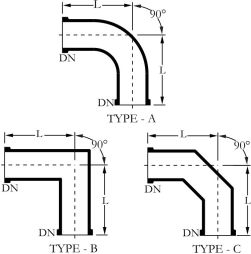

| DN | L | TYPE | CAT. REF. |

|---|---|---|---|

| 15 | 50 | A | HPB07/45° |

| 25 | 75 | A | HPB1/45° |

| 40 | 100 | A | HPB1.5/45° |

| 50 | 100 | A | HPB2/45° |

| 80 | 125 | B | HPB3/45° |

| 100 | 175 | B | HPB4/45° |

| 150 | 200 | B | HPB6/45° |

| 225 | 225 | B | HPB9/45° |

| 300 | 275 | B | HPB12/45° |

| DN | L | TYPE | CAT. REF. |

|---|---|---|---|

| 15 | 100 | A | HPB07/80° |

| 25 | 100 | A | HPB1/80° |

| 40 | 150 | A | HPB1.5/80° |

| 50 | 150 | A | HPB2/80° |

| 80 | 200 | B/C | HPB3/80° |

| 100 | 250 | B/C | HPB4/80° |

| 150 | 250 | B/C | HPB6/80° |

| 225 | 375 | B/C | HPB9/80° |

| 300 | 450 | B/C | HPB12/80° |

| DN | L | TYPE | CAT. REF. |

|---|---|---|---|

| 15 | 100 | A | HPB07/90° |

| 25 | 100 | A | HPB1/90° |

| 40 | 150 | A | HPB1.5/90° |

| 50 | 150 | A | HPB2/90° |

| 80 | 200 | B/C | HPB3/90° |

| 100 | 250 | B/C | HPB4/90° |

| 150 | 250 | B/C | HPB6/90° |

| 225 | 375 | B/C | HPB9/90° |

| 300 | 450 | B/C | HPB12/90° |

| DN | DN1 | L | L1 | CAT. REF. |

|---|---|---|---|---|

| 40 | 25 | 150 | 125 | HPBR1.5/1 |

| 50 | 25 | 150 | 150 | HPBR2/1 |

| 50 | 40 | 150 | 150 | HPBR2/1.5 |

| 80 | 40 | 150 | 150 | HPBR3/1.5 |

| 80 | 50 | 150 | 150 | HPBR3/2 |

| 100 | 25 | 200 | 150 | HPBR4/1 |

| 100 | 50 | 200 | 150 | HPBR4/2 |

| 100 | 80 | 200 | 175 | HPBR4/3 |

| 150 | 50 | 200 | 150 | HPBR6/2 |

| 150 | 80 | 250 | 175 | HPBR6/3 |

| 225 | 50 | 250 | 200 | HPBR9/2 |

| 225 | 80 | 250 | 250 | HPBR9/3 |

| 300 | 80 | 300 | 250 | HPBR12/3 |

| 300 | 150 | 350 | 250 | HPBR12/6 |

| DN | L | CAT. REF. |

|---|---|---|

| 15 | 75 | HPU07 |

| 25 | 150 | HPU1 |

| 40 | 175 | HPU1.5 |

| 50 | 175 | HPU2 |

| 80 | 225 | HPU3 |

| DN | DN1 | L | L1 | CAT. REF. |

|---|---|---|---|---|

| 15 | 15 | 125 | 75 | HPUO07 |

| 25 | 25 | 250 | 150 | HPUO1 |

| 40 | 25 | 275 | 175 | HPUO1.5/1 |

| 40 | 40 | 275 | 175 | HPUO1.5 |

| 50 | 25 | 275 | 175 | HPUO2/1 |

| 50 | 50 | 275 | 175 | HPUO2 |

| 80 | 25 | 350 | 225 | HPUO3/1 |

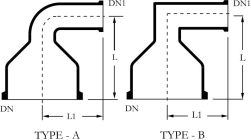

| DN | DN1 | L | L1 | TYPE | CAT. REF. |

|---|---|---|---|---|---|

| 40 | 25 | 225 | 150 | A | HPBT1.5 |

| 50 | 25 | 225 | 150 | A | HPBT2 |

| 80 | 25 | 275 | 200 | A | HPBT3 |

| 100 | 25 | 350 | 250 | B | HPBT4 |

| 150 | 25 | 350 | 250 | B | HPBT6 |

| 225 | 25 | 475 | 375 | B | HPBT9 |

| 300 | 25 | 550 | 450 | B | HPBT12 |

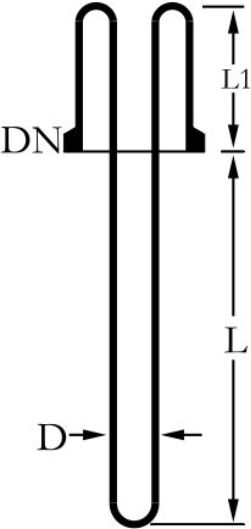

| DN | D | L | L1 | CAT. REF. |

|---|---|---|---|---|

| 25 | 12 | 100 | 50 | HTPBT1 |

| 25 | 12 | 100 | 50 | HTPBT1.5 |

| 25 | 12 | 100 | 50 | HTPBT2 |

| 25 | 12 | 100 | 50 | HTPBT3 |

| 25 | 12 | 110 | 50 | HTPBT4 |

| 25 | 12 | 135 | 50 | HTPBT6 |

| 25 | 12 | 160 | 50 | HTPBT9 |

| 25 | 12 | 200 | 50 | HTPBT12 |

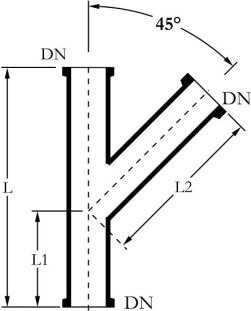

| DN | L | L1 | L2 | CAT. REF. |

|---|---|---|---|---|

| 15 | 125 | 50 | 100 | HPY07 |

| 25 | 200 | 75 | 150 | HPY1 |

| 40 | 250 | 100 | 175 | HPY1.5 |

| 50 | 300 | 125 | 200 | HPY2 |

| 80 | 350 | 150 | 250 | HPY3 |

| 100 | 450 | 150 | 350 | HPY4 |

| DN | L | CAT. REF. |

|---|---|---|

| 15 | 40 | HPBE07 |

| 25 | 50 | HPBE1 |

| 40 | 75 | HPBE1.5 |

| 50 | 75 | HPBE2 |

| 80 | 100 | HPBE3 |

| 100 | 125 | HPBE4 |

| 150 | 125 | HPBE6 |

| 225 | 150 | HPBE9 |

| 300 | 150 | HPBE12 |

| DN | L | CAT. REF. |

|---|---|---|

| 15 | 8 | HPBF07 |

| 25 | 8 | HPBF1 |

| 40 | 8 | HPBF1.5 |

| 50 | 8 | HPBF2 |

| 80 | 8 | HPBF3 |

| 100 | 8 | HPBF4 |

| 150 | 9 | HPBF6 |

| 225 | 9 | HPBF9 |

| 300 | 9 | HPBF12 |

| DN | L | CAT. REF. |

|---|---|---|

| 15 | 50 | HPX07 |

| 25 | 100 | HPX1 |

| 40 | 150 | HPX1.5 |

| 50 | 150 | HPX2 |

| 80 | 200 | HPX3 |

| 100 | 250 | HPX4 |

| 150 | 250 | HPX6 |

| DN | DN1 | DN2 | L | L2 | CAT. REF. | |

|---|---|---|---|---|---|---|

| 80 | 50 | 25 | 250 | 115 | 100 | HPXU3/2/1 |

| 100 | 25 | 25 | 250 | 110 | 110 | HPXU4/1/1 |

| 100 | 40 | 25 | 250 | 125 | 110 | HPXU4/1.5/1 |

| 100 | 50 | 25 | 250 | 125 | 110 | HPXU4/2/1 |

| 100 | 80 | 25 | 300 | 150 | 150 | HPXU4/3/1 |

| 150 | 40 | 25 | 250 | 150 | 150 | HPXU6/1.5/1 |

| 150 | 50 | 25 | 250 | 150 | 150 | HPXU6/2/1 |

| 150 | 80 | 50 | 300 | 175 | 150 | HPXU6/3/2 |

| 150 | 100 | 50 | 300 | 200 | 150 | HPXU6/4/2 |

| 225 | 40 | 40 | 300 | 185 | 185 | HPXU9/1.5/1.5 |

| 225 | 50 | 40 | 300 | 185 | 185 | HPXU9/2/1.5 |

| 225 | 80 | 40 | 300 | 210 | 185 | HPXU9/3/1.5 |

| 225 | 100 | 50 | 450 | 250 | 185 | HPXU9/4/2 |

| 225 | 150 | 80 | 450 | 275 | 210 | HPXU9/6/3 |

| 300 | 50 | 40 | 400 | 230 | 230 | HPXU12/2/1.5 |

| 300 | 80 | 40 | 400 | 275 | 230 | HPXU12/3/1.5 |

| 300 | 100 | 40 | 400 | 275 | 230 | HPXU12/4/1.5 |

| 300 | 150 | 50 | 450 | 300 | 230 | HPXU12/6/2 |

| 300 | 225 | 80 | 600 | 300 | 275 | HPXU12/9/3 |

| 400 | 40 | 40 | 400 | 275 | 275 | HPXU16/1.5/1.5 |

| 400 | 80 | 40 | 400 | 300 | 275 | HPXU16/3/1.5 |

| 400 | 100 | 40 | 400 | 300 | 275 | HPXU16/4/1.5 |

| 400 | 150 | 80 | 500 | 350 | 300 | HPXU16/6/3 |

| 400 | 225 | 100 | 800 | 450 | 300 | HPXU16/9/4 |

| 450 | 40 | 40 | 400 | 300 | 300 | HPXU18/1.5/1.5 |

| 450 | 80 | 40 | 400 | 320 | 300 | HPXU18/3/1.5 |

| 450 | 100 | 40 | 400 | 320 | 300 | HPXU18/4/1.5 |

| 450 | 150 | 80 | 600 | 380 | 320 | HPXU18/6/3 |

| 450 | 225 | 100 | 800 | 400 | 320 | HPXU18/9/4 |

| DN | D | L | CAT. REF. |

|---|---|---|---|

| 15 | 19 | 70 | HPHC07/.75 |

| 25 | 25 | 90 | HPHC1/1 |

| 25 | 19 | 90 | HPHC1/.75 |

| 25 | 13 | 90 | HPHC1/.5 |

| 25 | 07 | 90 | HPHC1/.25 |

| 40 | 25 | 100 | HPHC1.5/1 |

| 40 | 19 | 100 | HPHC1.5/.75 |

| DN | D | L | CAT. REF. |

|---|---|---|---|

| 15 | 19 | 40 | HPBHC7/.75 |

| 25 | 25 | 60 | HPBHC1/1 |

| 25 | 19 | 60 | HPBHC1/.75 |

| 40 | 19 | 75 | HPBHC1.5/.75 |

| 50 | 19 | 100 | HPBHC2/.75 |

For heating of piping and for controlling the temperature throughout the column, the jacketed pipe section is provided. Glass jacket is sealed to the pipe section using silicon 'O'ring and other sealing compositions.

*Permissible pressure in glass jacket

- DN 80 - DN 150 1.0 bar. g

- DN 225 - DN 300 0.5 bar. g

| DN | D | DN1 | L | L1 | L2 | CAT. REF. |

|---|---|---|---|---|---|---|

| 80 | 100 | 25 | 1000 | 850 | 750 | HPSD3/1000 |

| 100 | 150 | 25 | 1000 | 850 | 750 | HPSD4/1000 |

| 150 | 225 | 25 | 1000 | 850 | 700 | HPSD6/1000 |

| 225 | 300 | 25 | 1000 | 850 | 700 | HPSD9/1000 |

| 300 | 400 | 25 | 1000 | 850 | 650 | HPSD12/1000 |

Pipe section can also be provided with metal jacket. In metal jacket, maximum operating pressure permitted is 2.0 bar g in all the sizes. They are used not only to avoid heat loss for the purpose of saving energy but also where product temperature has to be maintained to prevent crystallising or undesirable reactions

| DN | D | DN1 | L | L1 | L2 | CAT. REF. |

|---|---|---|---|---|---|---|

| 80 | 100 | 25 | 1000 | 850 | 750 | HPSJ3/1000 |

| 100 | 135 | 25 | 1000 | 850 | 750 | HPSJ4/1000 |

| 150 | 188 | 25 | 1000 | 850 | 700 | HPSJ6/1000 |

| 225 | 262 | 25 | 1000 | 850 | 700 | HPSJ9/1000 |

| 300 | 345 | 25 | 1000 | 850 | 650 | HPSJ12/1000 |

© 2023 Heta Glass And Polymers PVT. LTD.

Design & Developed By : Dalia Web & Soft Solution